The system has dual safety protection devices which ensure the 4 roller plate rolling machines safe use. Unlike other solutions on the Market DAVI exclusive design provisions a planetary actuation of the side rolls whereas rather than being guided up and down the mechanism rotates around a pivoting point.

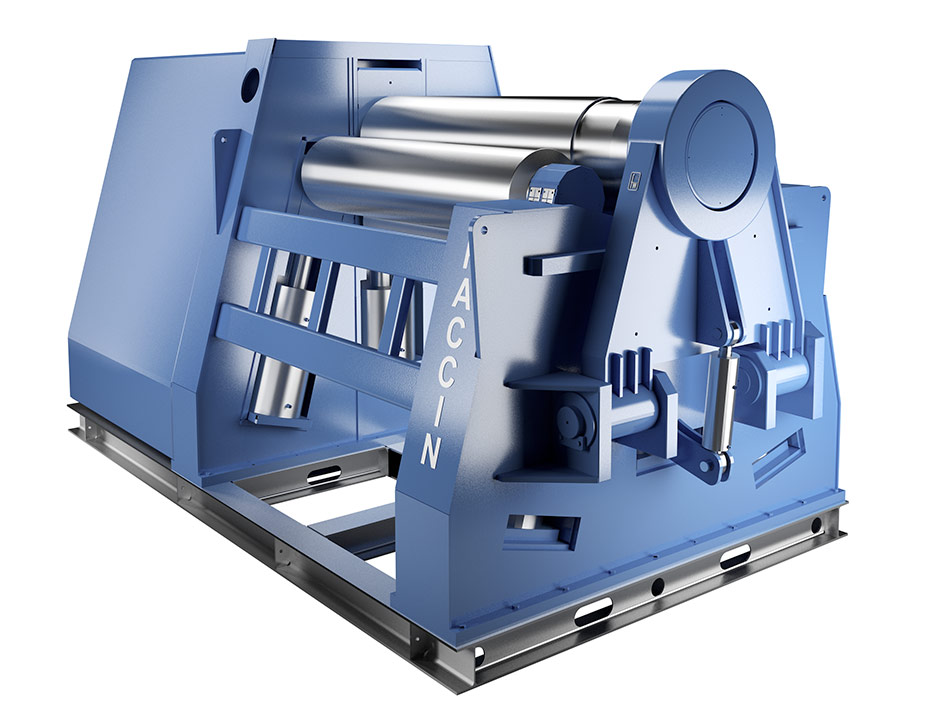

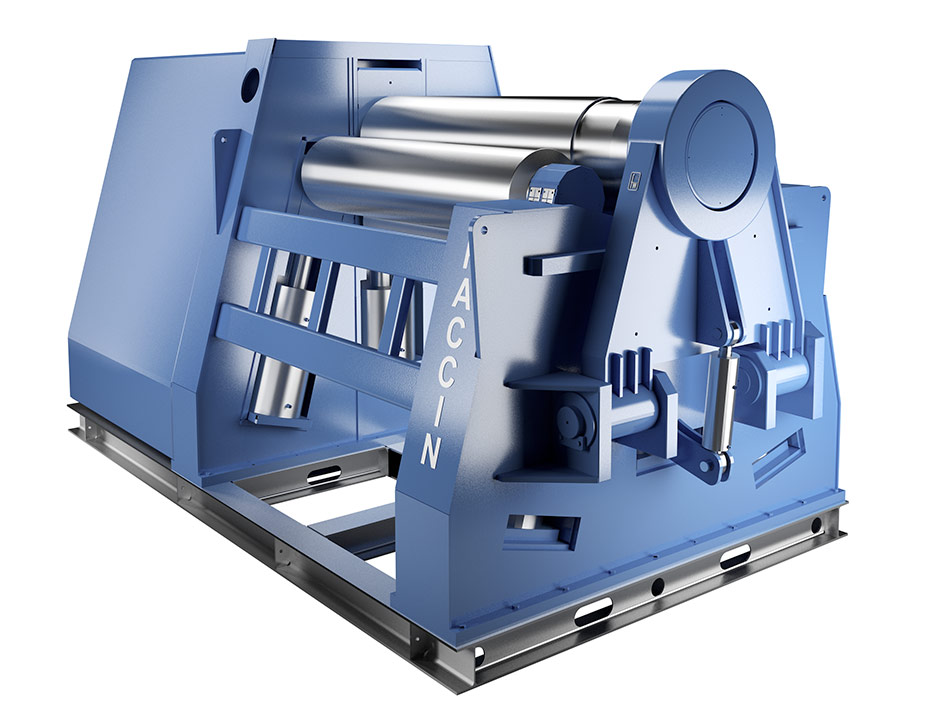

4 Roll Plate Bending Machine 4hel Faccin

An air filter ensures the normal breathing of the fuel tank and the evaporation of water.

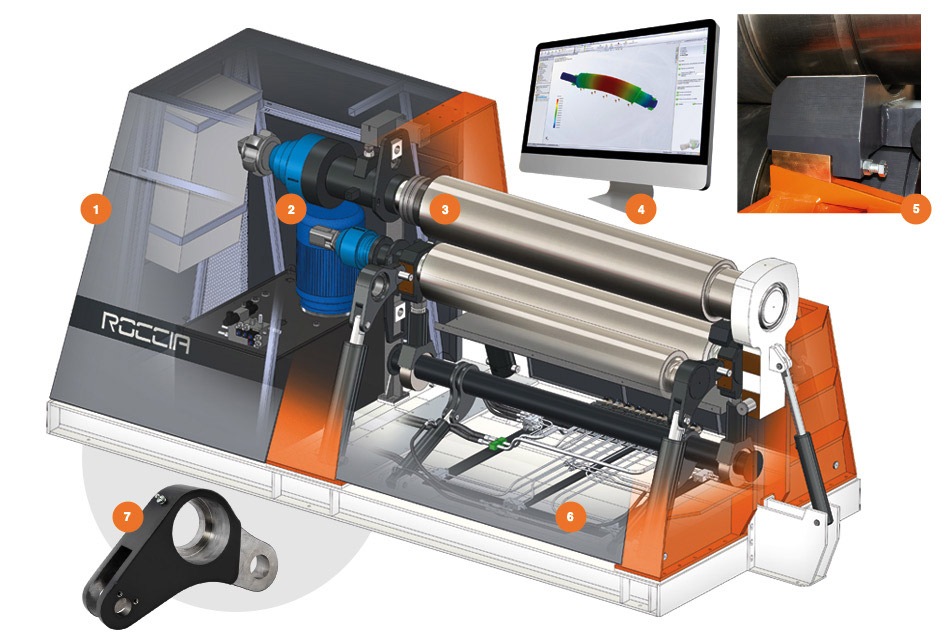

. ONE PHASE CYCLE No need to pre-bend. Accurate fast easy and intuitive it is the most high-tech plate roll for light gauge in the market. The machine is safe because of overload protection.

Hydraulic Press We also manufacture different types of Hydraulic Presses like H Frame Hydraulic Press C Frame Hydraulic Press. With our 4 roll machines the bottom roll moves up to hold the plate edge securely against the top roll while the side roll is raised to form an accurate pre-bend minimizing the flat zone on the plate edge. Upper roller is driven by hydraulic motor lower side roller rotation is driven by the friction between the steel plate and the roller.

After pre-bending the left end lower the rear roller to its original position and start the upper roller. MG four roll line is the easiest to operate plate bending machine thanks to its ability to pinch the plate between the 2 central driven rolls prebend the leading edge and rolling the body of the part along with the trailing edge all in one direction and in one pass. Upper roller position fixed bottom and side roller can lift move.

Pre-bending on a three roll machine requires that. The hydraulic system of EZHONG 4 roll plate bending machine design ensures the cleanliness of the system with oil suction and returns oil filters. So CNC plate rolling machinery use the high voltage and high current.

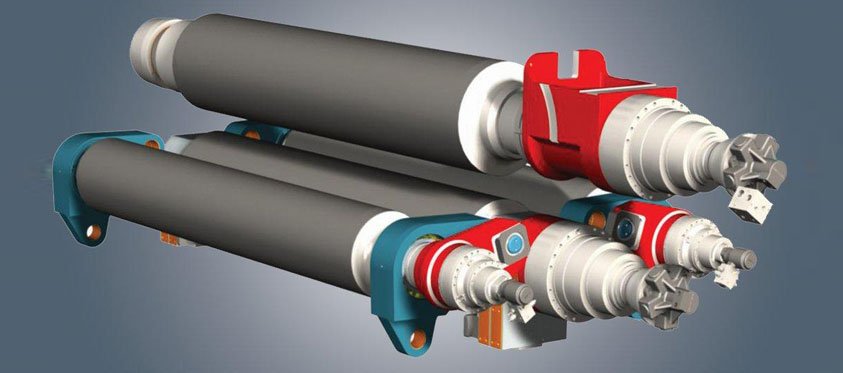

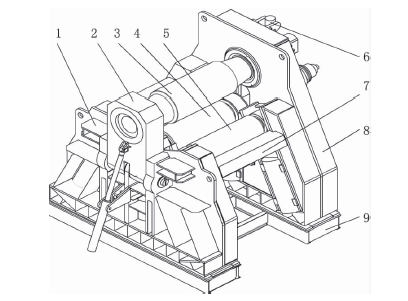

The bottom rolls can be mounted in slides or the rolls can move on a swing arm with a pivot at one end that is fixed. Tightest Achievable Diameters thank to Planetary Guides The bending power of a 4-roll machine is exerted to the plate by two side rolls. These design 4 roll plate bending machine are fully automatic and upgraded.

Bottom roller The bottom roller device is made of the. Quenching and tempering hardness HB 230 290. Similar to the 4-roll double pinch plate bending machine this design also allowed pre-bending both ends without turning the plate.

Hydraulic Press Repairing Our Story INFORCE is rated as a leading Plate Bending Manufacturers in India. If we dont think carefully about the protection and safety mechanism it will lead to disaster. 4 roll plate bending machine Our new 4 roll line offers many advantages.

It is the easiest hydraulic bending machine to use thanks to the ability to pinch the plate between the two motorized central rolls to make the pre-bending at the end and the bending thru the whole body in a single direction and in one pass. Bendmak 4-Roller CNC Bending Machines with superior engineering design and build quality will reduce operator dependency and offer a safer and more productive solution. These models offer more precise pre-bending and bending than our 3 rolls bending Machines These models have the ability to bend in different shapes.

The special process design of our four-roller plate bending machine makes the drum almost no straight edge and the processed metal drum manufacturer directly performs welding without secondary processing thus eliminating the processing cost. This Chinese company designs de. The upper roll is an important part of the bending machine.

The 4 roller plate bending machine uses the front roll to pre-bend the other end of the steel plate. The lower roller is fixed on the bearing seat. The Hydraulic 4 Rolls Hydraulic Plate Bending Machine is ergonomic user-friendly and handy.

When the steel plate follows the above. The upper roller of four roller plate bending rolls is drive roller lower roller and side roller are slave driven roller. Its position is fixed and can only be rotated.

Upper roll lower roll and double roll. The work roll of the four-roll plate bending machineroll consists of four rolls. In design to roll plate up to 10-15 mm 12 inch thick.

There can be a yoke with a fixed pivot on one end followed by the roll and some further distance out you can attach the cylinder. Our new line of 4-roll plate bending machines offer many decisive advantages. It is usually made of 42CrMo and tempered after rough machining.

This unique design also allows the plate to be clamped precisely between the upper and lower rolls thus minimizing the amount of flat ends on the formed plate. 4-Roll Plate Bending Machine Rolling Process Voltage and current There are many related actions in the mechanical part of metal plate rollers especially numerical control equipment. 380V Sheet Plate Rolling Machine Bending Plate Machine 40-500mm Diameter Contact Now Automated 2 Roll Plate Bending Machine Hydraulic Power 4 RevMin Roller Speed.

The machine provides easy operation. 4-roller plate bending machine MH series hydraulic CNC. The upper roller is the main drive roller and is embedded in the upper and lower frames through the bearing body.

This driven gear was powered by a hydraulic motor with variable speed. Deep Draw Hydraulic Press Dish End Hydraulic Press. Whether it is 3 rolls or 4 rolls plate bending machine Taian Smart Machine is the ultimate supplier to place your order with.

3 roll drive and variable speed was another huge step forward and is the design that many medium size machines use today. Plate Bending Machines repairing. There are various designs as to how the load is applied to the plate to be rolled.

4 Roller Plate Bending Machine Structure And Precautions Machinemfg

4 Roll Plate Bending Machine Jmt Usa Plate Bending Machines

4 Plate Bending Machine With Planetary Swinging Arms 4hep Faccin

Plate Bending 4rolls Hydraulic Plate Bending Machine 4r Hss 4 Roll Plate Bending Machine

4 Roll Plate Bending Machine Hr4wr

4 Roll Plate Bending Machine Hr4wr

4 Roll Plate Bending Machine Axeroll Hydraulic Plate Bending Machine

Load Analysis And Driven Power Calculation 4 Roll Bending Machine Machinemfg

0 comments

Post a Comment